A Fun-guide to the Past, Present and Future of Leather Materials

Humans are innovative. When they see a problem, they develop creative solutions to solve it. That’s true when it comes to leather: a strong, flexible and durable material for which humans have found a myriad of uses. The innovation? All of the unique materials humans have used to make leather. First, it was animals (like cows), then plastic, and now it’s … mushrooms?

Image credit: Getty Images

Early humans hunted wild animals for food, and used the rest of the animal (like its hide and bones) to make useful items. In cold areas, using an animal hide as clothing could preserve precious body heat. In warm areas, animal hides could be spread out as tents, providing valuable shade to escape the Sun’s heat.

Animal leather is a versatile material. Capable of being soft and durable, people around the world use animal leather to create clothing, footwear, tools, furniture, bags and sports equipment. When well taken care of, items made of animal leather can last for decades.

As human populations have grown, so too has the demand for leather, but the animal leather supply chain cannot keep up. Animal leather is a byproduct or coproduct of the beef and dairy cattle industry. So, even though demand has increased, the industry has not been able to match that with supply of new animal leather.

Petroleum-derived leather—which you may know as faux leather, plastic leather (pleather) or vegan leather—is one replacement for animal leather that has helped fill the gap. This synthetic leather is made from polyvinyl chloride (PVC) and polyurethane (PU), which are plastic-based materials.

Image credit: Getty Images

These substitutes help address the animal leather shortage issue, and are sometimes supported by those who have ethical and moral concerns about using animal-based products, but they also have a negative side effect: both pleather and animal leather have substantial and negative environmental impacts.

There is a newer, more eco-friendly option that might bloom in the industry: mushroom leather. Mushroom leather is made from mycelium. This mass of root-like structures of fungi are densely intertwined, making the material strong and durable like animal leather.

When it comes to water, waste, space and greenhouse gasses, mushroom leather is an environmentally friendly alternative to animal and petroleum-derived leather. Here are some highlights:

- Growing mushroom leather is reported to take less than 1/10 the water used in standard animal leather production.

- Lab-grown mycelium can be developed to exact specifications, eliminating waste from excess product. What do we mean? Well, have you ever seen a cow shaped like a jacket? (If you have, tell us immediately. That’s a newsworthy science story we need to know about!) Growers can produce mushroom leather in an exact shape, whether it’s a glove, bicycle seat or belt!

- Mushrooms for making leather can be grown vertically inside of buildings, minimizing the amount of land needed.

- Like petroleum-derived leather, mushroom leather is vegan as it does not use any animal products, which generally is cattle, the most polluting livestock on Earth.

- The mycelium are fed organic waste such as sawdust. Cows, on the other hand, require their food to be grown on separate land than where they live. Also neat? Any leftover materials from the mycelium harvesting can be composted.

- Creating animal leather is about a 2-to-3 year process from a cow being born to a leather product being made. Some mushroom leather companies can compress that timeline into as little as 8 weeks!

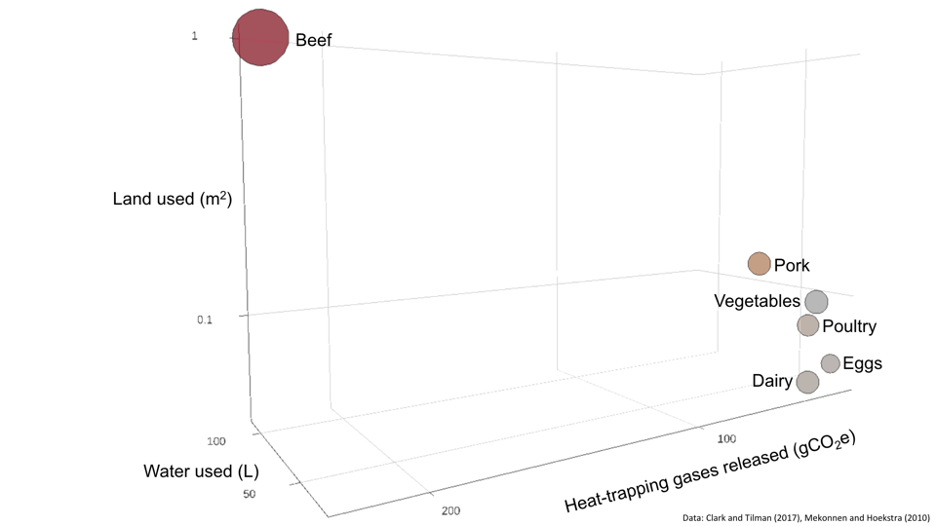

The land, water and heat-trapping gas footprint of 1g of protein from various sources.

Although many mushroom leather products are bio-based—meaning they’re made predominantly from materials derived from renewable ingredients found in nature—mushroom leather is not necessarily 100% plastic free. Furthermore, the invention of mushroom leather cannot have a large impact on the health of the planet unless consumer demand is high enough to make an impact on the production and use of pleather and animal leather. One way to increase consumer demand? Make mushroom leather affordable.

While the innovations are worth celebrating and the developments in leather heading in a positive direction, we’ll admit there’s still mush-room for improvement.